Black silicon carbide for processing alloy and glass

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB |

| Min. Order: | 10 Ton |

| Delivery Time: | 15 Days |

| Packaging: | 25kg/bag; 500kg/bag |

|---|---|

| Productivity: | 1000000T |

| Brand: | XING KAI |

| Transportation: | Land |

| Place of Origin: | NING XIA, CHINA |

| Supply Ability: | 10000T/M |

| Certificate: | ISO9001 |

| Port: | Tian Jin |

Basic Info

Model No.: SIC F180

Product Description

Product Introduction

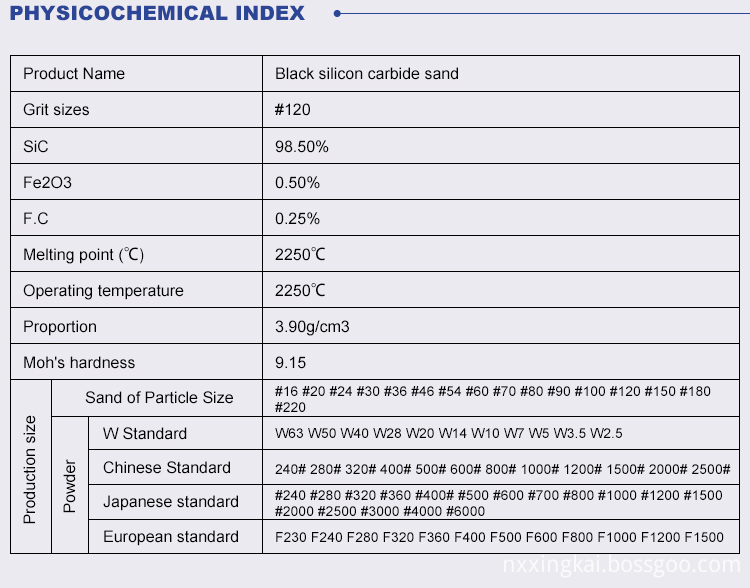

Black silicon carbide containing SiC about 95%, its Silicon carbide most of the material used for processing low tensile strength of materials, such as glass, ceramics, stone, refractory, cast iron and non-ferrous metals, etc. is higher than green silicon carbide Silicon carbide (SiC) is used quartz sand, petroleum coke (or coal), wood chips as raw material through high temperature resistance furnace smelting made.

Silicon carbide is also called moissanite. Silicon carbide is most widely used in the modern C, N, B, and other non oxide high technical refractory raw materials. Silicon carbide hardness is very high, the Mohs hardness is a magnitude 9.5, the second only to the world's most hard diamond (10). It with excellent thermal conductivity, is a semiconductor, high temperature resistant to oxidation. Low grade silicon carbide (containing about 85 per cent of the SiC) is an excellent deoxidizing agent, it can accelerate the speed of steel-making, and easy to control the chemical composition, improving steel quality.

Green silicon carbide containing SiC is about 97% above, good self sharpening, mostly for processing hard alloy, titanium alloy and optical glass, also used for honing the cylinder and fine grinding HSS Cutting Tools. In addition to cubic silicon carbide, it is a special process for the production of yellow green crystal, with the production of the abrasive tool suitable for the bearing of ultra precision machining, also can make the surface roughness from Ra32 to 0.16 micron Ra0.04 ~ 0.02 micron.

Application

The use of silicon carbide with corrosion resistance, high temperature, high strength, good thermal conductivity, impact resistance and other characteristics, silicon carbide on the one hand can be used for a variety of smelting furnace lining, high temperature furnace components, silicon carbide plate, lining, support, sagger , Silicon carbide crucible and so on. On the other hand, silicon carbide can be used for high temperature indirect heating materials in non-ferrous metal smelting industry, such as vertical tank retort, distillation tray, aluminum electrolytic tank, copper melting furnace lining, zinc furnace arc plate, thermocouple protection Tube, etc .; silicon carbide for the production of wear-resistant, corrosion-resistant, high temperature and other advanced silicon carbide ceramic materials; silicon carbide can also be made rocket lances, gas turbine blades. In addition, silicon carbide is also one of the ideal materials for highways, air runways and solar water heaters.

Transportation and package

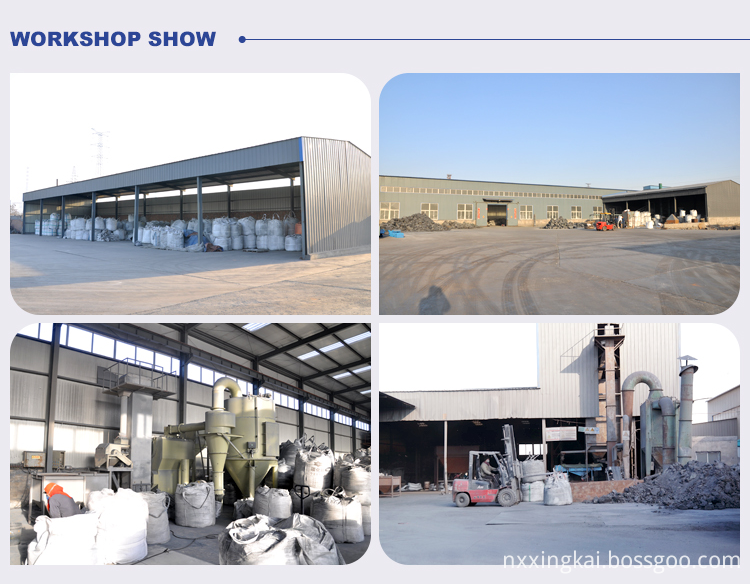

1. Transportation and handling: During the transportation process, the silicon carbide shall not be dragged with hook, should prevent mixing with hard materials. It should be light unloading to reduce packaging crushing.

2. Storage: The silicon carbide should be stored in a cool and dry place, to prevent rupture of bags, to prevent moisture and other substances to affect the product. Storage should away from sources of pollution.

3. Non-flooding: The silicon carbide is high abrasive, so in the transportation, storage and the process, we must absolutely prevent flooding to insure the quantity of the products.

Product Categories : Silicon Carbide > Silicon Carbide Fine Powder